My recent decision, to proactively fix a small leak on my PTT, turned into a full air suspension debug session.

I learned many useful details, which I hope you can keep in mind, when your car starts exhibiting air suspension issues.

Troubleshooting the air suspension is not super difficult, but it really helps to understand all components, and how they work together to keep the Panamera performing at its peak.

Terms below and ordering mostly match terminology in the FSM, to help reduce ambiguity.

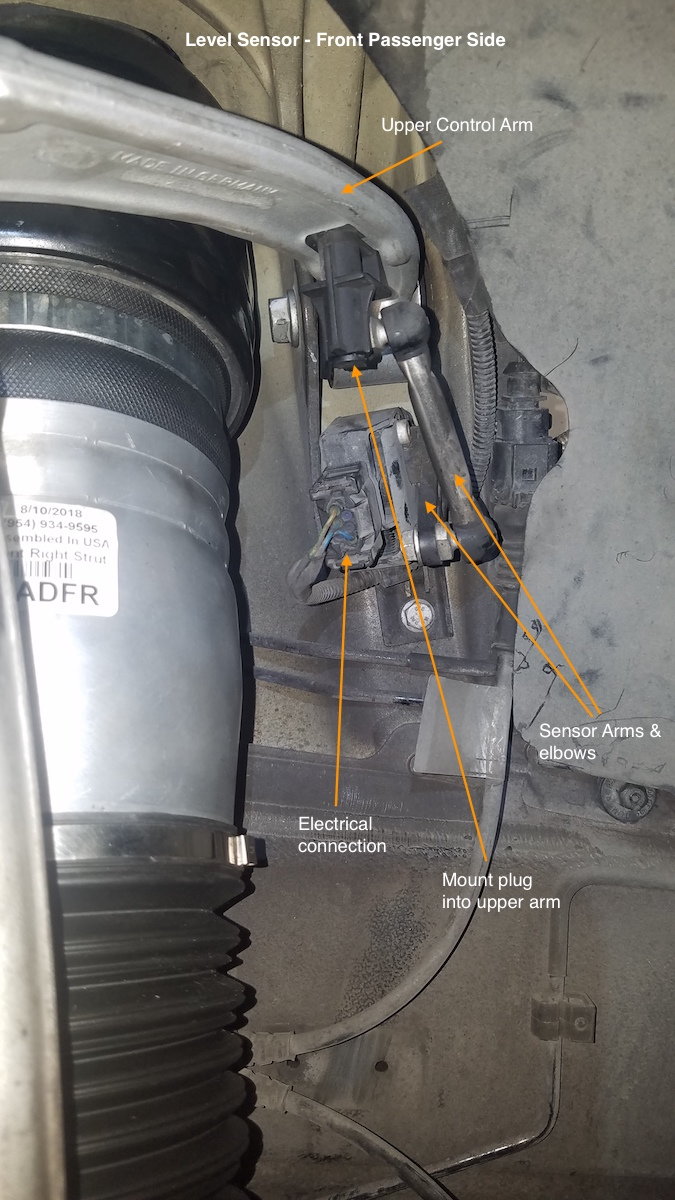

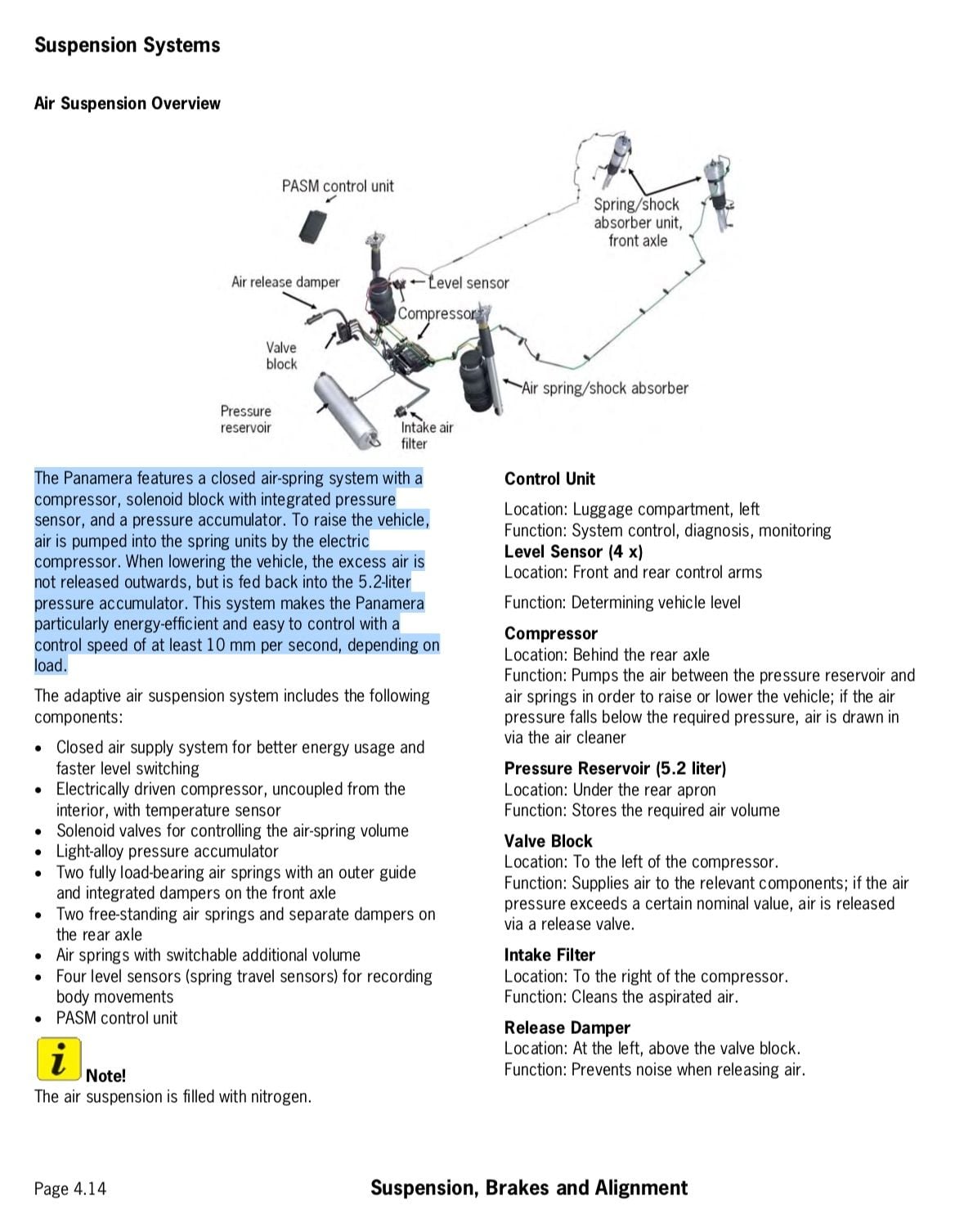

First – overview of the entire air suspension.

Look over the entire diagram and identify each of the components shown, so you can get a good feel for where each part is, how it connects to the rest of the system, and how the entire system is supposed to work as a unit.

PANAMERA AIR SUSPENSION COMPONENTS

Panamera air suspension is made up of the following pieces, which all must work well, in order for the suspension to work appropriately.

- Air shocks, front – air strut for front of car

There are two front air shocks, which have internal cavities, where compressed air is injected, to raise the car higher, lower it, make shocks stiffer, etc.

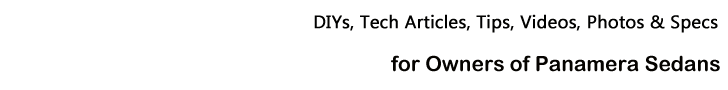

These front air shocks have rubber bladders, where the air is injected, to achieve desired function. These air cavities are made of rubber material, which, after few years, will deteriorate, and can start leaking air. The air can start leaking from the rubber material (bellows), or can lead out of the top of the shock, or the upper shock bushing. Leaking from bellows will not be easy to observe as they are mostly obstructed by the shock components. Leaking from upper shock bushing can be observed by spraying soapy water onto the top of the shock. Leak will manifest itself by soapy water making bubbles on top of the shock. The air shocks have 3 connections on the top side of each: Air line/tube (off center, different color for each shock), air shock sensor at center top of shock (detects shock expansion/compression with air), and electrical connection for valve that lets air in/out of the air shock (right near the air line). The air line connects to the air shock via a brass fitting, which ensures air tight connection between air line and shock. The sensors and electrical connections are connected to the ECU, so it can tell position of each corner, and adjust as necessary, or can turn electrical connections on/off, to control flow of air into/out of shock. Each air shock has a pressure regulated valve on it, making sure that there is some small amount of pressure in the tank at all times, to help prevent damage to the shock internals if it gets compressed hard (as in after new one put in and car is lowered onto new shock).- Air shock

-

-

- Air shock connectors

- Air shock

- Air shocks, rear – air strut with spring for rear of the car

These rear air shocks are similar to front shocks, but these reservoirs are separate from the struts that help support the car. The air bellows help raise or lower the car just as the front air shocks. Rear air shocks are assisted by vibration dampers mounted to the side of each shock. Same connections go to the top of each air shock for rear: Air line (different color for each side), electrical connection for valve in the shock, and sensor that detects if shock expands/compresses when air is adjusted.

The sensors and electrical connections are connected to the ECU, so it can tell position of each corner, and adjust as necessary, or can turn electrical connections on/off, to control flow of air into/out of shock.

Each air shock has a pressure regulated valve on it, making sure that there is some small amount of pressure in the tank at all times, to help prevent damage to the shock internals if it gets compressed hard (as in after new one put in and car is lowered onto new shock). - Vibration dampers for rear axle

These vibration dampers help rear shocks in absorbing chassis movements, making the rear stable while driving. - Level sensors

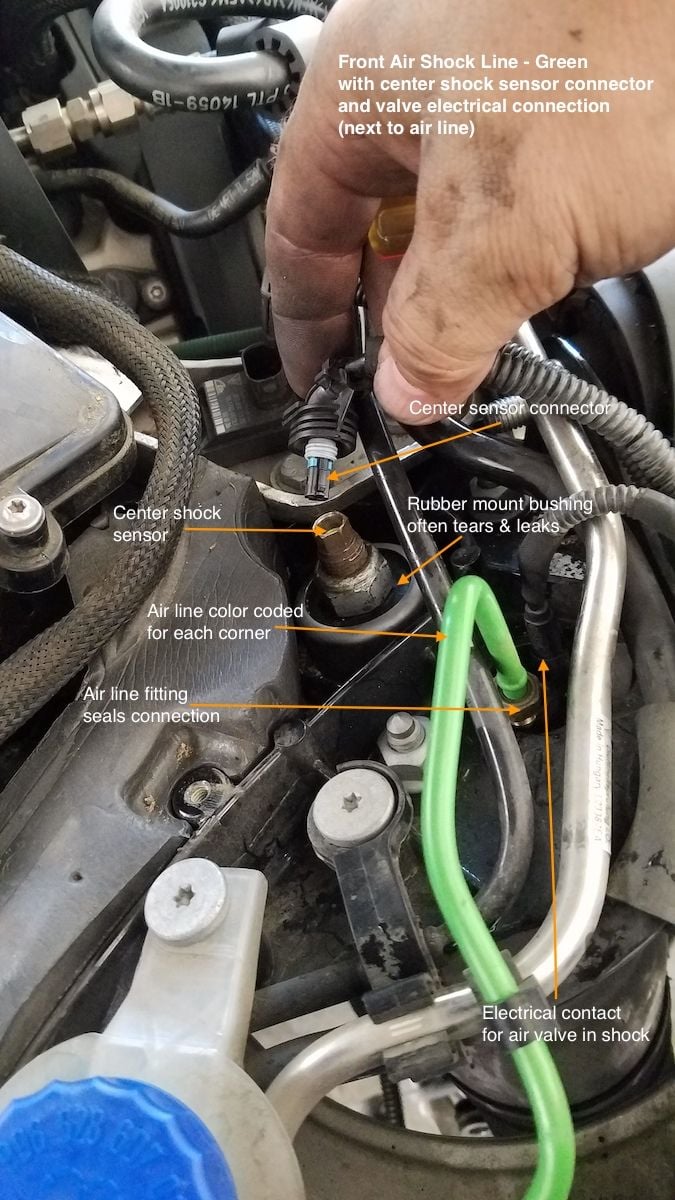

There are four sensors, each mounted on the upper control arm near each shock. These sensors detect if the corner of the car was raised or lowered, or if the particular corner of car is outside the ‘typical’ position (too high or too low). These sensors are responsible for error messages like ‘vehicle is extremely low’, etc. The sensors have one electrical connection, and two arms joined with an elbow that allows movement when car goes up or down. These sensors are connected to the ECU, so it can detect each corner position and adjust as necessary. There are additional sensors mounted on top of each air shock. These sensors detect the inflation/deflation of each shock, and can tell the ECU if the shock how much air is in each shock (so ECU knows if the suspension is stiff, loose, etc).- Level Sensor

- Level Sensor

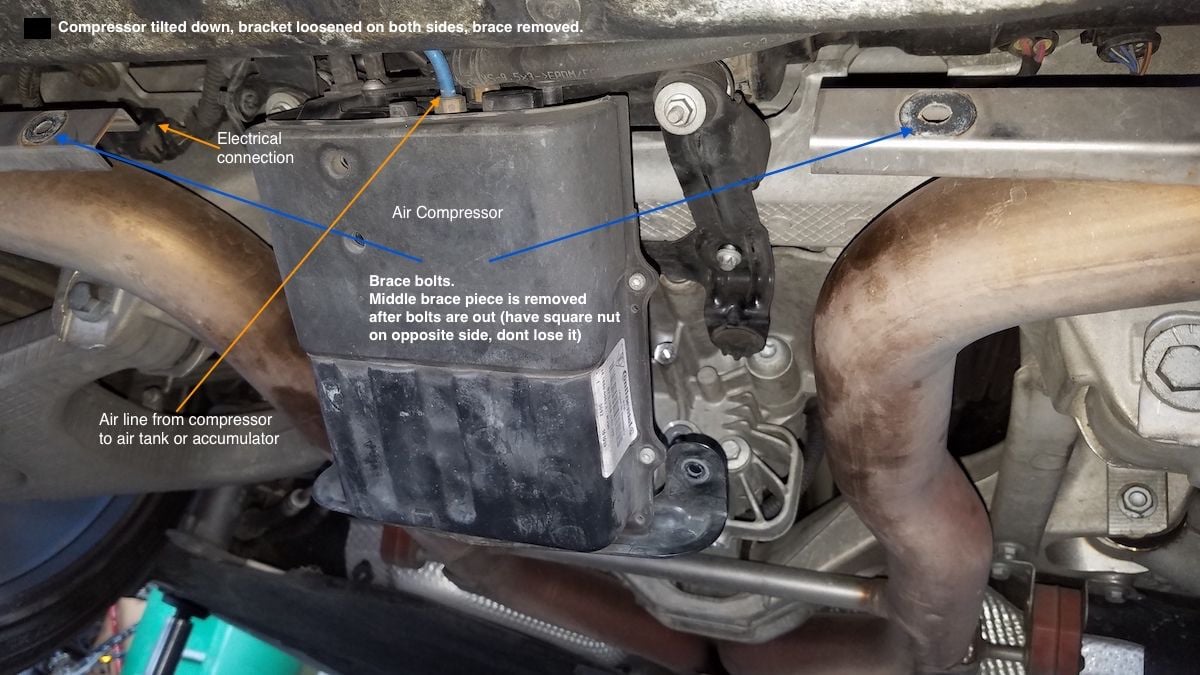

- Air Compressor

Sometimes this is called the air pump. This compressor is located under the car, behind the rear differential, under a protective shield. This compressor compresses air, and feeds it into the air tank. Its sole job is to make sure the air inside the tank, is at predefined pressure, so that the suspension can be adjusted quickly, per design. The Air compressor is connected to the ECU via electrical connections. It also has a filtered line coming out of it (see the pigtail in diagram, coming to the left and ending with a round structure). This round structure is an air filter, making sure clean air goes into compressor from outside, so it can be compressed and forced into the air tank. This compressor is also connected with a color coded air line, to the air tank itself.-

-

- Valve block

Sometimes this is called valve body or valve unit. This valve block is a group of solenoids, which, when energized (connected to electricity), perform some type of work. The work they do is simply to open a valve, allowing compressed air to either go into a shock, out of a shock to be vented out through a dedicated OUT connection on the block itself. This OUT connection is a plastic pipe which ends under the trunk near the bumper. When air is let out of shocks, the compressed air travels out of shocks, through the air lines, into the valve block, and through the OUT port, into the vent line, and is let out of the system (this is the muffled hissing sound you hear when your car is lowered). Normally, the valve block is not energized, and all valves are closed (no air is moving through the block). For any valve to be open, that valve must get powered from ECU, and corresponding solenoid is energized, opening the paired valve to allow air through. As soon as ECU removed electricity, the valve closes automatically. The valve block has an electrical connection that connects to the ECU. The ECU controls the opening/closing of each valve/solenoid in the block, when inflating or deflating each shock.-

-

- Air tank

Sometimes called the pressure accumulator (because it accumulates or collects compressed air). This is simply a metal tank, where compressed air is stored, so that when necessary, each shock can be inflated quickly. This air tank is connected to the air compressor with one line, and to the valve block with another line. Compressor feeds compressed air to the air tank, and if needed, air tank provides the system with compressed air via connection to valve block. - ECU or Leveling system control unit/PASM

This is the ECU or the leveling system control unit. It is a circuit board with electronics, that will turn on/off power to pieces of air suspension, will monitor sensors in the system, monitor position of each corner of car. This is the brain of the entire system. Issues with ECU, issues with detecting various sensors by the ECU, result in errors such as the air suspension system failure, etc. This ECU is connected to each shock, each shock sensors (monitor if inflating/deflating), each shock sensor near upper control arm (control height of the vehicle body), connected to valve block, controlling open/close of each solenoid/valve in the valve body, and is connected to the switches inside the car, the ones you press if you want to raise the car, make shock stiffer or softer, want to go into sport or sport plus mode, or back into the default comfort mode. - Switches inside the cabin to adjust suspension

These are the switches that you use to change the configuration of air suspension in your car, higher, lower, comfort, sport, sport plus, etc

OPEN OR CLOSED AIR SUSPENSION SYSTEM

Now, few things about the system, as I learned while debugging, and after speaking to mechanics that work on Panameras.

FSM states this is a closed system. Porsche mechanics would tell you it is a closed system.

Indy shop mechanics would tell you it is not a closed system.

I think the discrepancy is in the way you view the system itself. The shocks and valve block and air tank compose a closed system. Once pressurized, air remains in shocks and lines. When shocks are lowered though, they let air out of the system, through valve block, through the OUT port on the valve block, into tubing that vents air under the car behind the bumper. Similarly, the compressor draws filtered air from outside, and compresses it for the air tank.

So you can look at this system as a closed system (shocks, valve block, air tank only), or an open system, if you include the compressor and the OUT vent line from the valve block.

Whichever way you look at it, just be aware of how things work and you will be fine.

TYPICAL SYSTEM OPERATION

Now, lets go through typical operation of the air suspension system in the Panamera. This assumes car is working perfectly fine, no issues with suspension.

You get into the car in the morning. Car has been standing there overnight. Lets assume it got cold over night. Once you get in, car knows via sensors driver has just gotten into car.

You turn on the ignition and start the car. Sensors at center of each shock, and near upper control arms, tell the ECU what position the car is in. Car knows its last position from night before, when you parked the car.

So if for some reason (cold weather), pressure in any part of the suspension was decreased, after car is started (and all doors closed), the ECU will determine if the air tank needs to be pumped up to proper pressure.

If not, all good to go. If air tank pressure is a little low, compressor kicks in (relay in trunk of car will energize, and will close connection to turn on the compressor). The compressor will keep running on a timer and/or the

temperature sensor, and on a pressure in tank sensor. Once compressor starts, it will shut off if it becomes hot, or if the pressure in air tank reaches desired pressure, or if the compressor runs for more than a couple minutes.

The compressor stops because ECU disconnects electrical connection to the relay in trunk, removing electricity to relay, and therefore removing electrical connection to the power circuit that energizes the compressor.

Then, compressor stops running.

Once air tank is at pressure, ECU has already sensed how high your car is, how inflated or deflated your air shocks are. If the car is too high, air can be let out of the system to return to position dictated by switches in cabin.

If car is too low (got very cold outside), the ECU turns on all necessary solenoids/valves in valve block and in shocks, to allow compressed air to travel from high compressed area (air tank), to less compressed area (shocks).

Sensors in shocks will tell the ECU when to turn valves off, when proper height or stiffness is reached.

WHAT CAN GO WRONG, HOW TO DETECT & DEAL WITH REPAIR

Now, how does this system fail? Actually, very simple. You can divide it into 2 categories. Electrical (connections, sensors, ecu, etc), and mechanical (components, connections, lines, etc).

Shocks

If air shocks have leak in them (internally or at top of dampers for fronts), air will leak out, causing ECU to detect lower position of shocks, then making air compressor to work so the positions can be corrected.

If the leak is bad enough, the compressor will be asked to turn on way more often, causing it to heat up. If enough heat gets into the system, the air compressor piston/seals, etc can get broken, making compressor bad and

requiring either recondition kit with new pistons and seals, or a purchase of another compressor.

If there are leaks in the shocks themselves, the shocks have to be replaced. There is no way to repair these shocks on your own, since that would require disassembly of each sock, in a way that cannot be put back together again.

Special presses are needed to seal the shocks. So only way to fix leaking shocks is to buy new ones. You can get OEM brand new ones, or remanufactured ones. Many have found remanufactured shocks to be good fit, as price is about 30-40% of new OEM ones,

and they can work for very long time too. Choice dictated by your sense of what you need/prefer to get.

Air lines

You can also experience leaks in the air lines themselves. After years of use, a line can crack, causing leaking to occur from the shock itself (valve block is normally all closed, so any compressed air will leak out of the shock).

I think it is hard to crack air lines, unless work in the area on the car resulted in air lines being twisted, or pinched or forced, in a way to cause a crack. Near the shock connections in engine bay, it gets hot, so I can see these connections becoming brittle,

and cracking a bit. In these situations, you have to buy new air lines, or try to patch a found leak with epoxy, etc.

A good way to check if air line is leaking, is to disconnect from shock, and pull vacuum on it, while other end is connected to the valve block, and assuming valve block connection or internals are not leaking as well.

Then, you should see vacuum hold in the line. Otherwise the line has a leak and must be dealt with. Not fixing this will cause low pressure in shock all the time, making compressor over work, and being broken eventually.

Level sensors

Sometimes the level sensors near, or on the shocks, will become defective. This is usually manifested by the system not being able to detect that one or more shocks has been raised or lowered, or if stiffness has changed inside a shock.

If a level sensor goes bad, after button is pressed to raise car, you can see car raising, but can see messages on cluster that the system is faulty. Another example is changing modes to sport or sport plus, and ECU saying

on cluster air suspension system fault, or inability to enter the mode. As side note, if you cannot enter sport or sport plus mode, you will usually see other errors on console, along with limiting car power.

Car thinks something bad going on with suspension when trying to enter sport or sport plus mode, and will disable these modes based on errors. These additional errors normally go away after issue is fixed.

Normally, if level sensors go bad they will need replacement. Repair is a diy thing and often sensor is junk when broken.

Air compressor

Yet another common failure is the air compressor. This device makes sure the air tank is always at correct pressure, so that suspension changes can be done quickly (they say under 4 seconds).

If there is a leak in suspension, the air tank is asked to refill shocks much more often. This results in compressor working much more often to keep the air tank refilled.

You can start your car, close all doors, and stand by passenger side muffler. Listen for low tone humming coming out. That’s the compressor. If you hear it coming on often over 20 minutes of idle, you have suspension issues.

You can troubleshoot compressor issues by codes. Normally suspension system failure can manifest as bad compressor. If you do not hear compressor kick in at all when you press button to raise suspension, chances are, compressor bad.

If you hear mechanical sounds that sound other than an electrical mattress inflator, you can suspect compressor.

Sometimes the relay goes bad, which typically will manifest as compressor not kicking on at all, or compressor being on all the time (this one usually results in relay bad).

Any time you replace compressor, replace relay as well. This ensures bad relay does not damage new compressor too. New relays have been changed slightly, altering voltage and current they can provide through them, to help compressor.

Valve block

Another place common to fail, is the valve block itself. Age can cause pressure fittings on any of the air lines to valve block, to become leaky. Then you can purchase these air fittings and replace in the valve block.

Problem with that is that often the block starts leaking internally too. Most of the time, the entire valve block is replaced. New one comes with fittings too.

To detect if valve block connections leak, you spray soapy water onto the air lines and fittings, and you would see air bubbles coming from fittings. You cannot test internal failures unless valve block itself becomes bad.

In this case, some valves will become stuck, manifesting in one corner being stuck low or high, or maybe all corners stuck in one position, despite using buttons to try switch to different configuration.

If only one corner is stuck, maybe two, chances are block needs replacement.

Air tank / pressure accumulator

It is hard to envision air tank failing, but it is possible something wrong with the lines makes the tank work bad. Not many things can make tank go bad, except for some puncture making leaks in tank, or lines.

ECU / Leveling system control unit

If the ECU goes bad, the entire system is no longer being monitored or controlled. This means your can wont raise, wont lower, wont change any settings for shocks, etc. The brain of the suspension is dead.

Therefore the entire suspension is dead. If nothing happens when you press any buttons, and compressor does not kick in, and car does not change height, but car has not slammed down (corners do not appear deflated),

it is a good sign the ECU is the problem.

Switches inside cabin

If you press buttons to change height, change mode, etc, and nothing happens, you can suspect the switches in the cabin. Usually one or two will not work, but other will. It is unusual for all suspension related buttons to stop working at same time.

If you can change modes, but cannot change stiffness, suspect buttons. Air suspension system failure errors are sometimes caused by buttons (since car is not responsive to button changes).

Those would be one of last things I would suspect to go bad though in typical suspension setup debug.

Sometimes, there is a combination of more than one item going bad. For example, you can experience a shock leaking, and while doing debug you accidentally crack an air line.

Or air shock goes bad and slams down, causing a level sensor to go bad as well.

In cases of suspension failures that have no obvious results, you will have to debug independent systems first, to make sure you know exactly where the issue is.

PD OF PROBLEMS & REPAIR

Start with shocks that appear to be leaking. Use soap water on top of shock to see if bubbles form. If yes, you know shocks need replacing. Then, do not remove any air lines. Crawl under car and spray valve block.

If bubbles form at connections, block is bad too. Sometimes valve block is bad internally, and if you cannot determine if good/bad, dish out the 100 bucks or so for a new one.

Unfortunately, only PIWIS2 system has debugging steps built in for air suspension. Other systems can only read and clear faults. So you wont be able to ID valve block bad/good unless you get wiring diagram,

identify which pins carry the 12V to specific valve in the block, so you can manually energize the valve and cause it to open (checking if works ok or not). You can use needle to pierce insulation at wire, to power it with 12V battery.

Air lines should be connected to valve block if you want to determine if they leak. Disconnect line at a shock and use small pump to put some vacuum on it. See if it remains. If it remains, that line is not leaking.

If line cannot hold vacuum, it has a crack. Then you will have to hunt down where the crack is. Normally at either end (seldom does it appear somewhere in middle of line).

If still cant find line leak, time to replace the line (each line is in sections with join connector,

up to you how to handle replacement – entire line or a section at a time).

Line leaks would be lesser on priority to check unless someone has been playing with removing lines from shock or from valve block, accidentally cracking one. IF you see a crack, you can try to epoxy it after wrapping with some adhesive.

Your choice.

Compressors will start making bad sounds before they go bad. There is a piston inside the compressor, with plastic rubber seals, which rub against a sleeve, while air is compressed. If the rubber plastic damages due to heat (running too long), compressor will stop running (will be too hard to move piston and ECU will tell relay to disconnect from power).

Anytime you change compressor, replace relay to make sure bad relay does not break new compressor. Remember, a relay is a mechanical way to close/open a circuit with electricity/magnets. Once electricity is added,

magnets force metals to contact, allowing electricity to flow. Once electricity is removed, magnets no longer work, forcing metal contacts away from each other (these contacts are spring loaded, so if magnetic field removed, spring forces contacts apart).

We have covered air shocks already, but it is possible for them to leak where you cannot spray to see the leak. If you spray top of shock and see no leaks, but then you see car raise the corner, only to see that corner again over time, the shock has an internal leak.

Must be replaced, repair not possible without specialty tools and presses.

By now, I covered components of the air suspension system in the Panamera, what each component does, how it is connected to the rest of the system, how it all works together, along with some troubleshooting tips.

Hope this will help others in their course to make another Panamera drive perfect. Let me know if you have opinions on this info. Thank you.